Definition of Thermal Transfer Overprinting

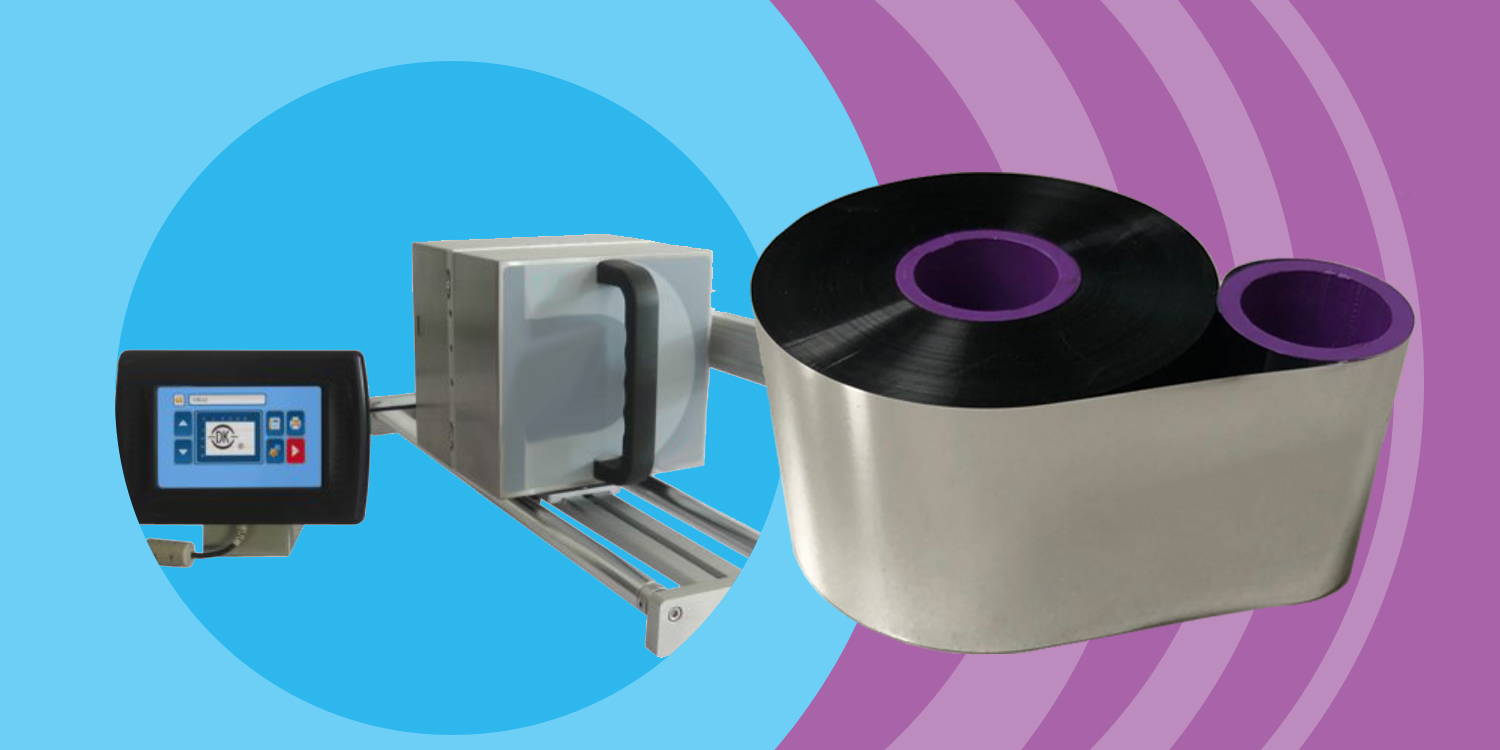

Thermal Transfer Overprinting is a digital printing technology that applies a code to flexible packaging such as a flexible film or label by using a thermal printhead and a wax-resin or resin thermal transfer ribbon. It is widely used in food, medical and pharmaceuticalindustries, including a wide variety of applications, such as wrapped confectionery, bagged snacks, candy bars, sleeve wrappers for bottles, fresh and frozen foods like vegetables, meat, poultry, pharmaceutical and nutriceutical labels etc.

Near Edge Printing

Near Edge Printing and TTO (Thermal Transfer Overprinting) are interchangable. Near edge printing technology is used in thermal trasnfer overprinter. In TTO printer, in order to achieve higher print speeds, the near edge print head is angled approximately 45°, with the heating elements located at the edge of the print head. Since the media only comes in contact with the ribbon as it passes under the print head’s heating elements, the ink transfer must be instant. The distance between where an image is printed and where the ribbon and receiver separate from each other is significantly shorter when compared to flathead printers. Therefore, near edge ribbons must contain a release layer which allows the ink to quickly transfer to the substrate. This unique ribbon chemistry limits ribbon type to wax/resin and resin black and color thermal transfer ribbon formulations.

The printhead in TTO printer comprises a ceramic coating, covering a row of thermal pixels at a resolution of 12 printing dots per mm allowing for high resolution codes. The print information transfers to the thermal print head and the individual printing dots are heated as required. The ink in the ribbon is transferred onto the material in the predefined area of the package.

Benefits of Thermal Transfer Overprinting versus Analog Technlogies

Thermal Transfer Overprinter (TTO) technology provides remarkable quality and accuracy to flexible film packaging by using a thermal printhead and a wax-resin (or resin) thermal transfer ribbon. Near-edge thermal printing guarantees the perfect balance of high print speed and print quality. The floating head can be adjusted to the thickness of the printed materials. Also Near-edge thermal printing can print on the most extreme media with the high print speed up to 40 ips (inch per second).

Improved Print Quality

Thermal Transfer Overprinter uses a 300dpi (dots per inch/12 dots per mm) printhead that produces consistent and repeatable high resolution codes.

Ability to Print Real-time Variable Data

TTO gives you the ability to print variable information including dates, lot codes and time etc. Analog coding technologies, such as hot stamp or ink roller use fixed stamps and therefore it is not possible to code real time data onto the packaging.

Increase Uptime

TTO (Thermal Transfer Overprinter)'s design ensures that it is fast to change ribbons. Usually the ribbon length can be as long as 1,200 meter. This allows longer uptime of the printer.

Increase Efficiency

Different from hot stamps that require a warm-up period to bring the type holder to proper temperature, TTO technology can go from power up to printing in less than 60 seconds. This advantage gives TTO much more power in flexibility and productivity on film packaging applications.

Reduced Ribbon Cost

TTO (Thermal Transfer Overprinter) ensures to keep the unused ribbon a minimum, which is to maintain a 0.5mm gap between prints. This allows more prints per ribbon roll and ensure the highest possible print efficiency.

How to select Thermal Transfer Ribbons for TTO (Thermal Transfer Overprinter)

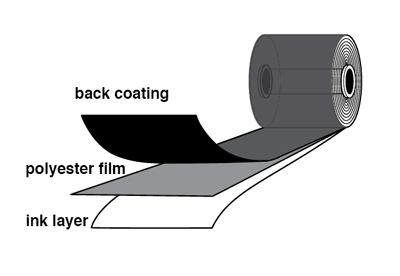

Structure of the TTO Ribbon

Structure of the TTO Ribbon

TTO (Thermal Transfer Oveprinter) ribbon consists of three layers, a thin layer of dried link, a layer of polyester film and a layer back-coated with lubricant to increase the life of your printhead. Because the print substrate for TTO (Thermal Transfer Overprinter) is flexible packaging, the ink layer of TTO ribbon is either wax/resin mixed or resin only.

W603 Wax/Resin Ribbon for Standard General Purpose Applications

General purpose applications of wax/resin ribbon includes wrapped confectionery, bagged snacks, candy bars and sleeve wrappers for bottles, salty/savory bagged snacks, fresh and frozen foods like vegetables, meat and poultry, dried fruit and candy. Wolfbarco's W601 wax/resin mixed ribbon is a UL-recognized premium wax/resin ribbon delivering superior image durability is the ideal ribbon for these general purpose flexible packaging applications. W601 offers excellent abrasion and heat resistance, excellent print darkness and high-definition characters and images. This ribbon can print up to 10 ips utilizing less printhead energy than competitive wax/resin formulations. Check out W603 Wax/Resin Ribbon here.

W605 Premium Wax/Resin Ribbon for Special Applications

Like W602 wax/resin, W605 is a UL-recognized premium wax/resin ribbon. W605 utilizes a thinner polyester base material resulting in a more thermally responsive ink, allowing the product to provide resin-like performance, at lower printhead energies and faster printer speeds more typical of wax/resin products. W605 Provides extra adhesion and super durability. It is the ideal ribbon for medical, pharmaceutical, and electronic applications. Example applications include glossy labels, pharmaceutical and nutriceutical labels, cosmetics, nutritional and ingredient statements. Check out W605 Premium Wax/Resin Ribbon here.